By: Robert Tate, Automotive Historian/Researcher

Images: Courtesy of the National Automotive History Collection

Posted: 09.02.2015

The Oakland Motor Car Company was organized in 1907. Later, they began manufacturing Pontiac automobiles for the consumer market.

In January, 1926, the first Pontiac vehicle was manufactured for the auto industry. It was created to fill the gap between the Chevrolet and the Oldsmobile production vehicles. The company name was changed to Pontiac Motor Company in 1931-32 when Pontiac took over all production facilities.

Final Inspection on 1939 PontiacAt a cost of $15 million, the Pontiac manufacturing facility was located on 135 acres. The plant was known as the daylight plant because of the amount of glass used in the construction. This facility in Michigan was one of the homes for Pontiac until it was closed in later years. It was a modern production facility where many of the men and women were highly trained and skilled craftsmen that always accomplished great quality results as they assembled Pontiac automobiles.

Final Inspection on 1939 PontiacAt a cost of $15 million, the Pontiac manufacturing facility was located on 135 acres. The plant was known as the daylight plant because of the amount of glass used in the construction. This facility in Michigan was one of the homes for Pontiac until it was closed in later years. It was a modern production facility where many of the men and women were highly trained and skilled craftsmen that always accomplished great quality results as they assembled Pontiac automobiles.

For example, the men and women would work within the factory at Pontiac with over 150 powerful Pontiac engines from aluminum pistons to crankshafts along with connecting rod and pistons that could be produced in one single hour.

Other Pontiac assembly line responsibilities included giant presses that were capable of exerting pressures up to 2,500 tons which were used in stamping out fenders, hoods, bumpers and other manufactured parts for the assembly line workers. Pontiac workers also had to work with small parts for assembly line production. The small parts sometimes were supplied by outside firms that had to be constantly checked to insure an adequate stock at all times. The lack of one tiny part could cause the entire assembly operation to be suspended until the part was restocked.

1958 Pontica Body DropPontiac factory workers also participated during the war time efforts as well. After the last vehicle rolled off the Pontiac assembly line, the Pontiac factory workers began to take a part mile after mile of overhead conveyors. Huge machines were then torn from concrete areas by Pontiac factory workers and placed into storage yards.

1958 Pontica Body DropPontiac factory workers also participated during the war time efforts as well. After the last vehicle rolled off the Pontiac assembly line, the Pontiac factory workers began to take a part mile after mile of overhead conveyors. Huge machines were then torn from concrete areas by Pontiac factory workers and placed into storage yards.

Workers with drills would cut gaping holes in the floors to set a foundation for heavier machinery that was needed for Tank and plane production manufacturing. Word had come from Washington that all existing war plants were to be enlarged. One of the Pontiac Motors war production assignments was the manufacture of the Bofors 40 mm field gun along with parts for tanks for the U.S. Army and high-volume production of aircraft-launched naval torpedoes along with other parts as well.

After the war had ended, post-war Pontiac models began their manufacturing process on Sept. 13, 1945. However, the full line of 1946 Pontiac models did not appear until June 10, 1946, due in part to the United Auto Workers Union striking General Motors on Nov. 21, 1945.

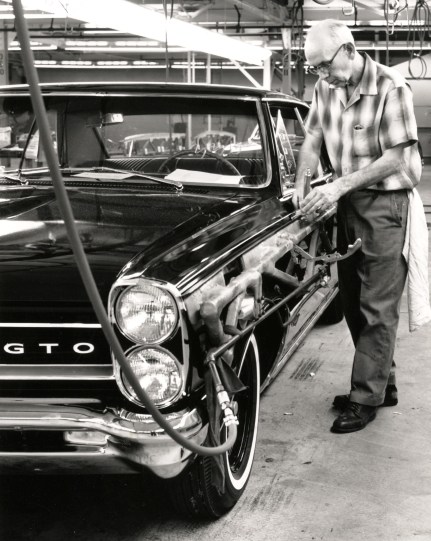

1965 Factory Worker Striping the GTOOne of the first factory workers that started with the Oakland Motor Car Company was Charles J. Long, who had been with Oakland/Pontiac assembly since 1919. He worked as a foreman, tool trouble-shooter and on special assignments and was considered a great factory worker and was very much a part of Pontiac manufacturing assembly line operations for many years.

1965 Factory Worker Striping the GTOOne of the first factory workers that started with the Oakland Motor Car Company was Charles J. Long, who had been with Oakland/Pontiac assembly since 1919. He worked as a foreman, tool trouble-shooter and on special assignments and was considered a great factory worker and was very much a part of Pontiac manufacturing assembly line operations for many years.

To all the men and women, including Charles Long, who were a part of our great automotive heritage and its great labor movement, who helped to build and shape Pontiac automobiles on the assembly line; honor is given.

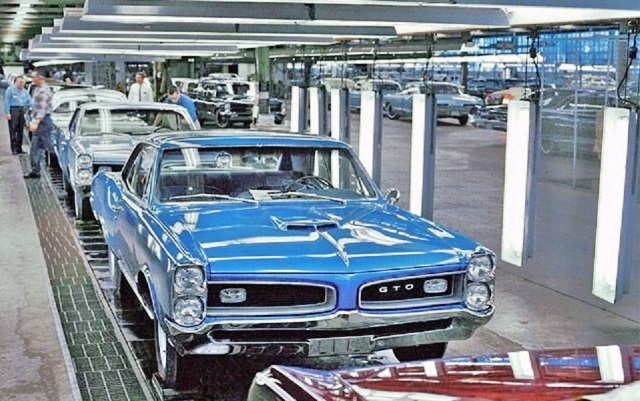

1966 GTO on Production LinePontiac sales continued to increase during the 1950s and 1960s. In 1959, Pontiac Motor Division had to hire over 3,000 factory line workers along with adding an extra factory shifts just to keep up with factory sales for the consumer market demanding over 217,303 Pontiac models. On March 14, 1962, General Motors celebrated its 75 millionth vehicle. This special milestone in Pontiac’s history was a joyful occasion for many Pontiac workers.

1966 GTO on Production LinePontiac sales continued to increase during the 1950s and 1960s. In 1959, Pontiac Motor Division had to hire over 3,000 factory line workers along with adding an extra factory shifts just to keep up with factory sales for the consumer market demanding over 217,303 Pontiac models. On March 14, 1962, General Motors celebrated its 75 millionth vehicle. This special milestone in Pontiac’s history was a joyful occasion for many Pontiac workers.

As the 1960's moved forward Pontiac began manufacturing the popular G.T.O models along with the first generation Fire-birds, and the popular Grand Prix models as well. The assembly line workers became very busy manufacturing Pontiac's for the high demand throughout the 1960's and the early 1970’s.

1970 Pontiac Grand Prix Assembly LineBy the time General Motors celebrated its 75th Anniversary, technology, robots and lasers were a part of the Pontiac assembly line process featuring scanners that could verify dimensions of openings in car bodies or even check dimensions of a windshield. It was the beginning of the new age technology and computers being featured within the work place at Pontiac Motor assembly. Today many of the Pontiac manufacturing plants and processes are no longer with us. However, the great men and women and their families who contributed to the legacy of assembly line workmanship will always have a special place in automotive history.

1970 Pontiac Grand Prix Assembly LineBy the time General Motors celebrated its 75th Anniversary, technology, robots and lasers were a part of the Pontiac assembly line process featuring scanners that could verify dimensions of openings in car bodies or even check dimensions of a windshield. It was the beginning of the new age technology and computers being featured within the work place at Pontiac Motor assembly. Today many of the Pontiac manufacturing plants and processes are no longer with us. However, the great men and women and their families who contributed to the legacy of assembly line workmanship will always have a special place in automotive history.

A special thanks to Robert Tate, Automotive Historian and Researcher, for donating the story to the MotorCities Story of the Week program. Photographs are courtesy of the National Automotive History Collection. (Bibliography: Gunnell John. “75 Years Of Pontiac Oakland” Crestline Publishing 1982. GM Folkes No. 2 February 1940. Published by Public Relations General Motors News.)

For further information on photos please visit http://www.detroitpubliclibrary.org/ or email This email address is being protected from spambots. You need JavaScript enabled to view it.. Please do not republish the story and/or photographs without permission of MotorCities National Heritage Area.

If you would like to contribute an article for the MotorCities newsletter, email This email address is being protected from spambots. You need JavaScript enabled to view it. or call 313-259-3425.